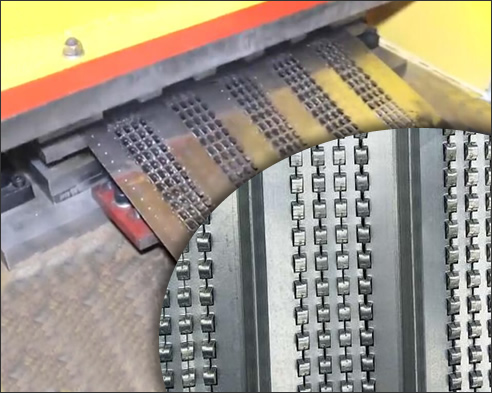

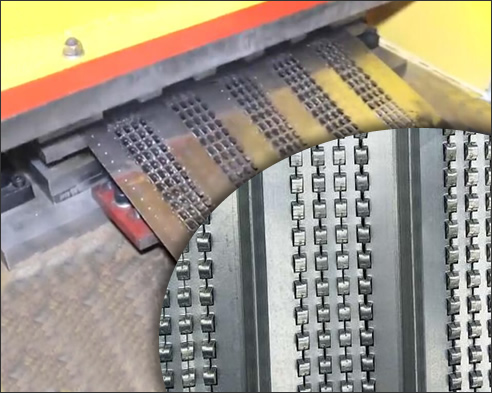

Hi rib lath formwork machine including:

Manual de-coiler - Press - Roll Forming Machine - Computer Control Cabinet - Automatic Cutting Shear - Run-out Tables-Tool Box

Hy Rib Lath Machine for manufacturing 0.36mm hy-rib formwork mesh

Main parameters of machine

Press Capacity: 120tonnage

Floor space:25m X 2.5m

Machine Width:1.5m

Machine Length:20m

Material: Galvanized steel

Output: 250-290meter per hour

Hi rib lath raw material thickness: 0.3 to 0.4mm

Production Line of High Rib Lath Making Machine for 450mm Width

Supply to Turkey and other countries.

This hi rib lath making machine can be used to process steel galvanized sheet with thickness up to 0.5 mm

Designed production capacity of 200 sheet /8 hours

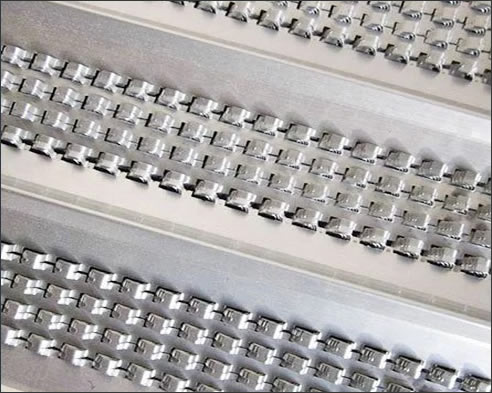

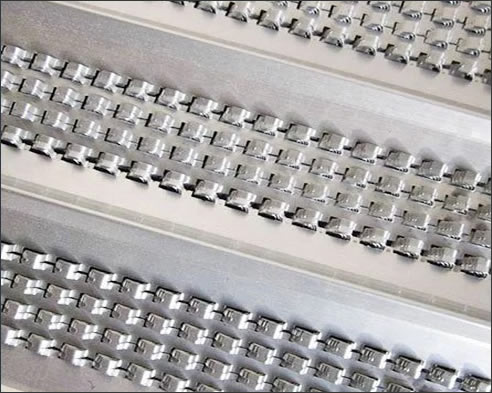

Finished hi rib lath products:

| Width (mm) |

Length (mm) |

Rib Height (mm) |

Rib Distance (mm) |

| 450 |

2200 |

14-20 |

90 |

One complete line set consists of the following:

A. Un-coiler

- 1. Brake Motor: 3HP; Voltage: 415/50Hz, 3 phase.

- 2. Loading capacity: 3000kg.

- 3. Coil specification: O.D: 1,500mm, I.D.: 480-520mm; material width: 500mm max.

- 4. Response to the main machine's punching speed, automatic feeding material.

- 5. Emergency switch.

B. Main Machine

- 1. Motor: 10HP; Voltage: 415/50Hz, 3phase

- 2. S.P.M.: 500-600 stroke/min.

- 3. Speed: about 5-6 meter per minute

- 4. Height adjustable range: approximately 3-5mm.

- 5. Lubrication device: 1 set.

- 6. Air clutch: 1 set

- 7. Die: one set [ raw materials thickness: 0.3~0.4mm ]

C. Forming roller Machine and Shear 2 in 1

Forming roller

- 1. Motor: 5HP; Voltage: 415/50Hz, 3 phase.

- 2. Rollers: 9-11 steps to forming and leveling

- 3. Product length counter (encoder): 1 set

Shear: hydraulic power system

- 4. Motor: 2HP; Voltage: 415/50Hz, 3 phase.

- 5. Cut-off length: 3000mm Max. [setting from control cabinet]

- 6. Cutting blade: 1 set. Blade material: SKD11, hardness HRC 60°.

- 7. A cable control for operating moving (connections parallel to those of the command panel).

- 8. Protective device: 1 set.

- 9. Emergency switch.

D. Finished product gathering rack

E. Electric control cabinet

- 1. Voltage: 415/50Hz.

- 2. Industrial Main machine interface: 1 set. Inverter: Mitsubishi.

- 3. Roller speed and product length & quantity by set-up method on control panel.

- 4. Emergency switch.

- 5. Electrical drawings, manual (in English) tool box.

Gathering Rack (Finished Products)

Raw material: Galvanized steel / Stainless steel

Plate thickness: 0.45mm ± 0.05mm