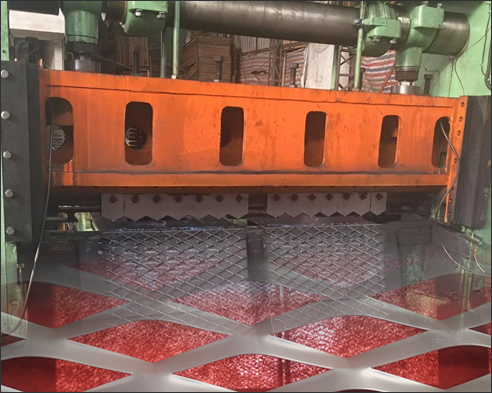

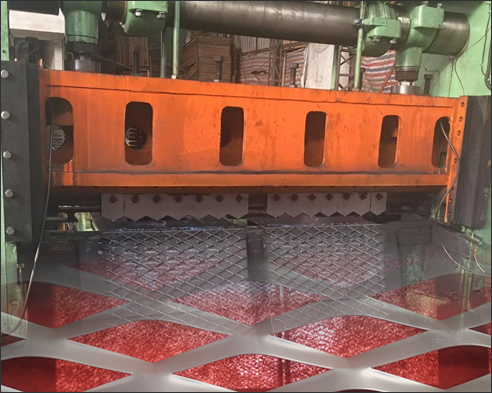

Expanded metal machine can make expanded mesh, used for diamond mesh lathing, corner beads and other stretched metal mesh products.

Expanded metal mesh machine can expand and stretch all kinds of steel and iron plate.

Export Types

Metal Expanding Machine, Supply to Brazil

Expanded sheet metal machine for hot rolling and galvanizing with thickness range 1-4 mm and maximum width 2000 mm.

Mechanic / Hydraulic

Guided by Two Columns

GPM 70

Capacity of 63T

Length: 1/8

1.500mm Steel Metal

Export to Brazil

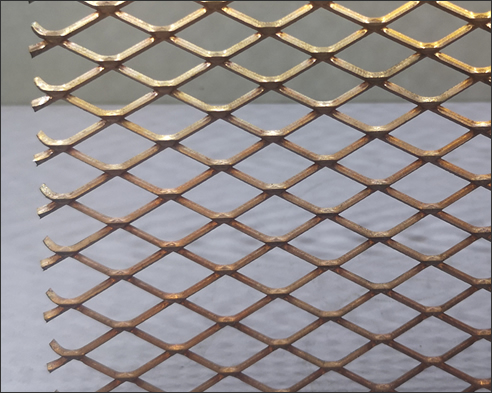

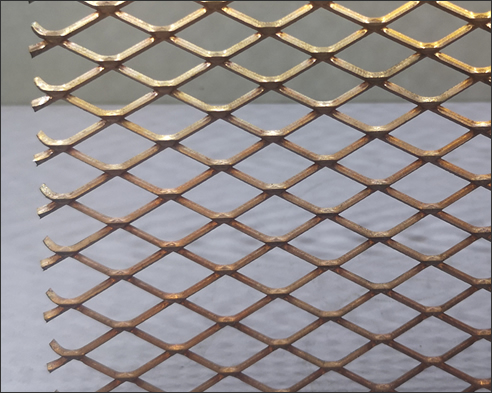

Expanded Metal Machine Supply to Egypt

Machine Specifications:

Width up to 1250 mm

Thickness from 0.5 to 3 mm.

LWD: up to 200 mm.

Finished expanded mesh product:

Diamond expanded metal mesh in carbon steel galvanized

One Set of Metal Expanding Machine for Steel and Stainless Plate Expanding

Producing process: De-coiler (Material coils) - Main Machine (Expanding) - Finished Products

One complete set of equipment consists as follows:

A. De-coiler :

- Motor: 1HP Voltage: 415/50Hz. 3phase

- Load: 1 tons

- Raw materials: thickness 0.3-1.0mm width: 200mm Max ID: 480-520 OD: 1000mm Max.

B. Expanding Machine:

- 1.Motor: 5HP[with inverter]; Voltage: 415/50Hz. 3phase

- 2.Stroke per minute: about 0-700 times.

- 3.Stroke length: 10mm

- 4.Raw material: width:150mm max Thickness: 0.3-1.0mm

- 5.Servo feeder: 0.3-2.0mm [W: strand width]

- 6.Mesh size: SW 1-10mm LW 2-20mm

- 7.Cam: 1 piece [for LW] [per one size]

- 8.Punching height adjustable range: approximately 1-2mm.

- 9.Punching die: 1 set [will make according to the sample or drawing]

- 10. Electric control cabinet: 1 set

- 11. Electrical drawings

- 12. Tool box: 1 set

C. Forming roller machine:

- 1. Motor: 3HP; Voltage: 415/50Hz, 3 phase.

- 2. Rollers: 9-11 steps to forming and leveling

- 3. Product length counter (encoder): 1 set

- 4. Speed: 3.5~4 meter per minute

Shear: hydraulic power system:

- 5. Motor: 2HP; Voltage: 415/50Hz, 3 phase.

- 6. Cut-off length: 3000mm Max. [setting from control cabinet]

- 7. Cutting blade: 1 set. Blade material: SKD11, hardness HRC 60°.

- 8. A cable control for operating moving (connections parallel to those of the command panel).

- 9. Protective device: 1 set.

- 10. Emergency switch.

Gathering Rack (Finished Products)

Raw material:

Galvanized steel / Stainless steel

Plate thickness: 0.45mm ± 0.05mm